Spacer Fabric Title: a Title

2020, TC-2 Jacquard Woven

Warp: Tencel

Weft: elastic hemp, elastic cotton, polyester (neon), silk, thermoplastic

This sample study was focused on ways one can add dimension to a fabric through only on-loom, structure-based processes. This is the first of many structure tests, and is the beginnings of what became my thesis on folding fabrics.

One of the wonders of jacquard weaving is that one is not limited by the shafts of the loom they are working on. In industry, this is typically used for intricate figuring of a fabric, but an oft-overlooked advantage is that one can quickly and easily test, modify, and examine complex structures that would be too timely a task for a conventional loom.

The idea of static and dynamic yarns working in opposition with one another is a central idea in many of my projects. The tension between static and dynamic yarns, in combination with the right structures, can be used to the weaver’s advantage to create characteristics that would not have been possible otherwise.

![]()

One of the wonders of jacquard weaving is that one is not limited by the shafts of the loom they are working on. In industry, this is typically used for intricate figuring of a fabric, but an oft-overlooked advantage is that one can quickly and easily test, modify, and examine complex structures that would be too timely a task for a conventional loom.

The idea of static and dynamic yarns working in opposition with one another is a central idea in many of my projects. The tension between static and dynamic yarns, in combination with the right structures, can be used to the weaver’s advantage to create characteristics that would not have been possible otherwise.

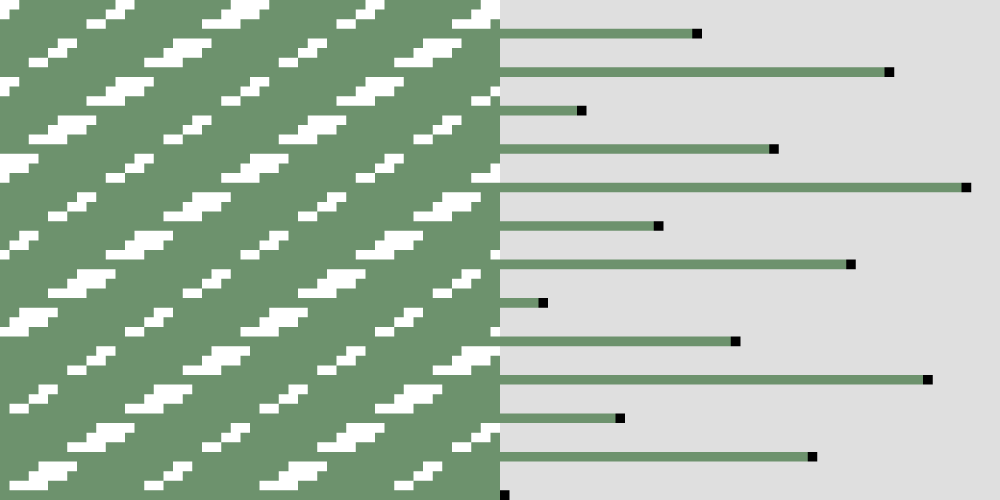

As pictured above, the fabric is set up as a doubleweave with the outer layers in twill. An enlarged satin pattern hides within the twill, and allows the thermoplastic weft to connect the two layers. When woven, the fabric is completely flat.

The finishing process is simply washing the fabric once off the loom. This allows for the elastic to shrink up, which leaves the thermoplastic thread with nowhere to go but up, giving the cloth dimension.

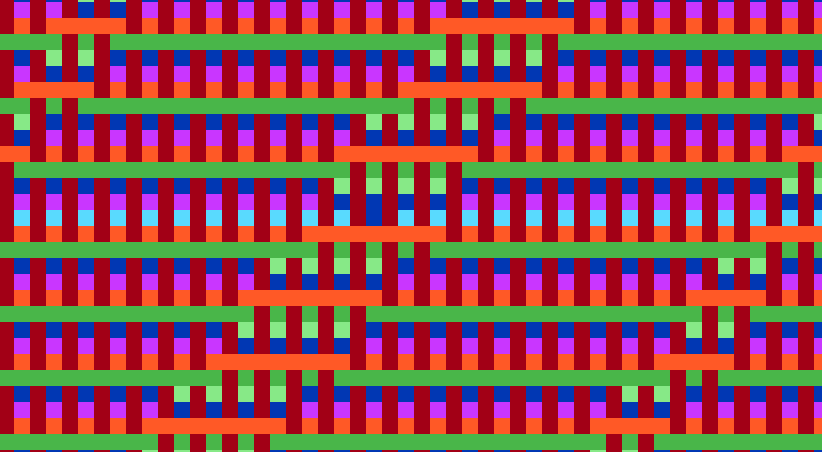

Structure closeup:

Red--Top warp

Blue--Bottom warp

Green--Elastic hemp and cotton, top weft

Light Green--Elastic hemp and cotton, bottom weft

Orange--Neon poly and silk, top weft

Magenta--Neon poly and silk, bottom weft

Cyan--Thermoplastic weft